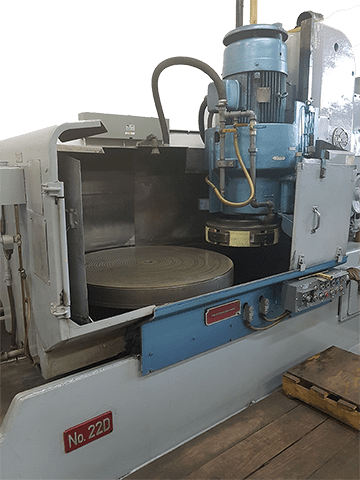

Our Capabilities

We can accomondate single or mulity-face grinding on soft or hardened steel. Grinding of all stainless steels.

- 3 Blanchard Rotary Grinders

- 42” Diameter Capacity x 20” High Clearance

- 48” Diameter Capacity x 20” High Clearance

- 70” Diameter Capacity x 32” High Clearance